Metallurgy

-

越南和发荣桔钢铁股份公司200万吨热回收炼焦项目分两期建设,每一期年生产焦炭100万吨。其中备煤、湿熄焦、筛焦按照年产焦炭200万吨总体设计建设,热回收炼焦一期按照年生产焦炭100万吨设计建设。

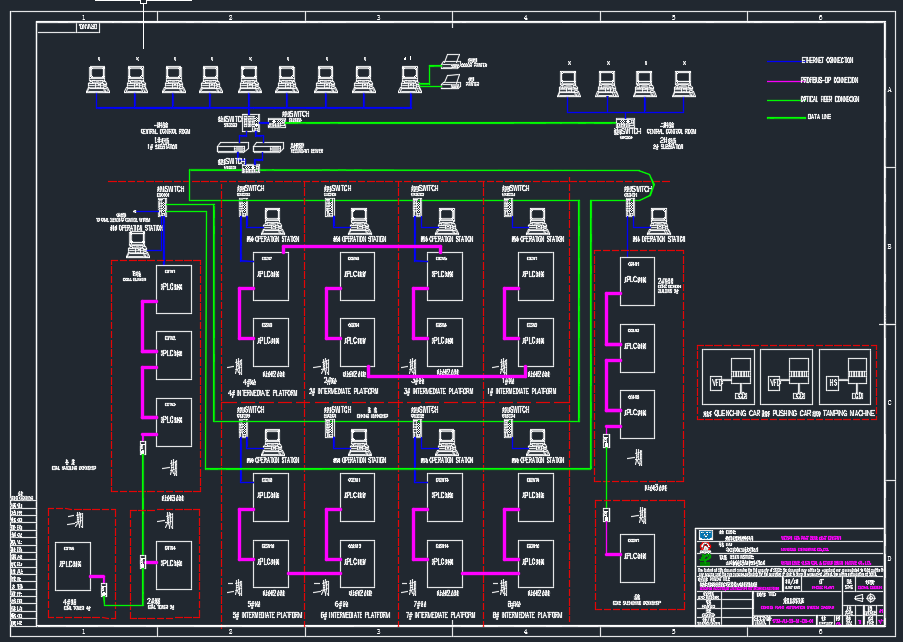

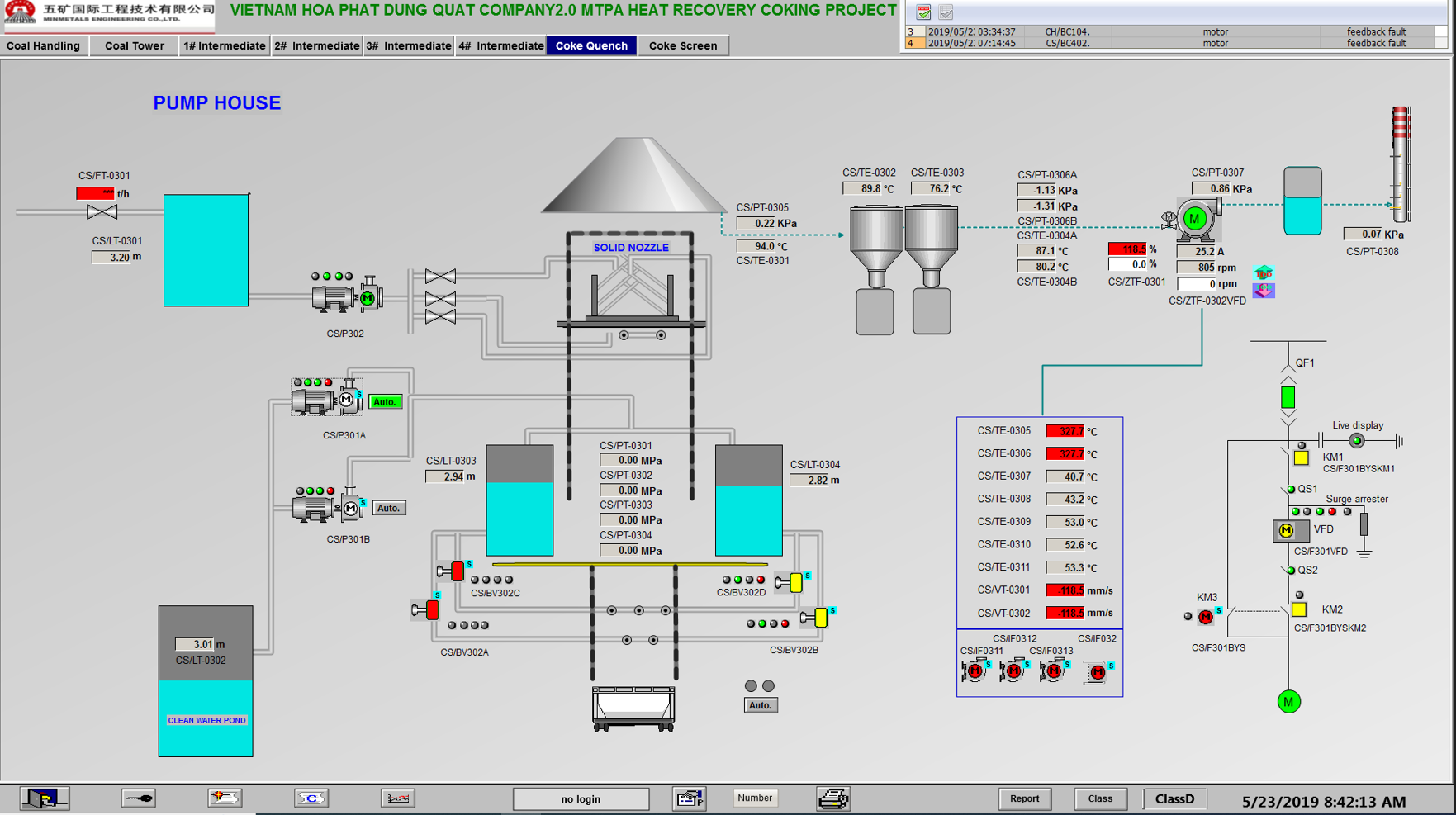

本项目设计范围包括:备煤工段、炼焦工段、湿法熄焦工段、筛焦工段。备煤工段、筛焦工段/,炼焦工段、湿法熄焦工段采用冗余的PLC控制。其中备煤工段的控制系统由输煤控制系统和配煤控制系统组成,称重式皮带给料机配煤控制系统、螺旋卸料车控制系统和备煤上料自动控制系统由制造厂成套供应

The 2 million ton heat recovery Coke project of Vietnam Helpha Rongju Iron & Steel Co., Ltd. will be constructed in two phases, with each phase producing 1 million tons of coke annually. Among them, the reserve coal, wet quenching coke and screening coke are designed and constructed in accordance with the annual output of 2 million tons of coke. The first phase of thermal recovery coke is designed and constructed in accordance with the annual production of 1 million tons of coke. Scope includes: the project design for coal, coking section and wet coke quenching section, screen coke section. Coal preparation section, coke screening section /, coke making section, wet coke quenching section adopts redundant PLC control. The control system of the coal preparation section is composed of the coal delivery control system and the coal blending control system. The coal blending control system of the weighing belt feeder, the control system of the screw unloading truck and the automatic control system of the coal loading are supplied by the manufacturer in complete sets